1) Comprehensive PCB Designing Services:

PCB Layout Editing We specialize in precise and optimized PCB layout editing services that enhance the functionality and manufacturability of your designs. Whether you’re modifying an existing board or refining a prototype, our team ensures meticulous trace routing, component placement, and adherence to design rules for seamless integration and performance.

Digital, Analog & Mixed-Signal Designs From high-speed digital circuits to intricate analog and mixed-signal designs, we bring deep expertise across the spectrum. We tailor each solution to meet the specific demands of your application, ensuring signal integrity, low noise performance, and system reliability.

Simulation & Analysis We offer advanced simulation and analysis services to validate your designs before fabrication. Our simulations cover signal integrity, power integrity, thermal management, and EMI/EMC performance, helping to reduce costly rework and accelerating your product’s time to market.

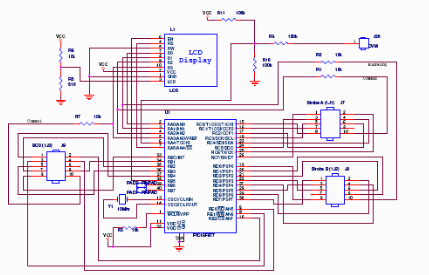

Schematic Creations Our schematic creation services lay the foundation for robust designs. Using industry-standard tools, we translate your concepts into detailed electrical schematics with logically arranged components, clear annotation, and full design documentation to support the entire design cycle.

Electronics Design Services We provide end-to-end electronics design solutions, from initial concept development to final prototype delivery. Our interdisciplinary approach integrates hardware, firmware, and design for manufacturability to deliver innovative and production-ready electronics.

PCB Design Services Our PCB design services encompass everything from single-layer to multi-layer boards for various applications. We focus on design accuracy, space optimization, thermal efficiency, and reliability, aligning with your electrical and mechanical constraints.

High-Speed Designs For high-frequency, high-speed circuitry, we offer expert-level design solutions that maintain signal fidelity under demanding conditions. Careful attention to impedance control, differential pair routing, and layer stack-up ensures optimal performance in speed-critical applications.

FPGA Designs Our FPGA design services provide custom logic design, optimization, and verification tailored to your system requirements. We work with leading FPGA platforms, supporting everything from simple glue logic to complex data processing tasks integrated with your PCB.

Industrial & Rugged Designs Designed for harsh environments, our industrial and rugged PCB solutions feature robust construction, wide temperature tolerance, and protection against shock, vibration, and moisture. Ideal for sectors like defense, energy, and transportation.

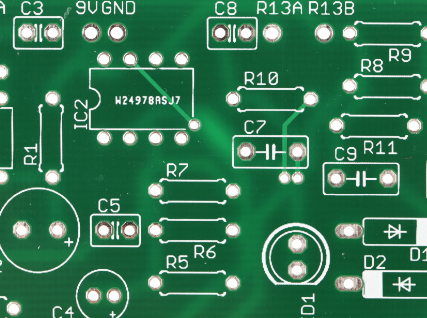

PCB Reverse Engineering We offer reliable reverse engineering services for legacy or undocumented PCBs. Whether you’re looking to recreate a discontinued product or improve an existing design, we reconstruct schematics and layouts while ensuring compliance with your desired specifications.

2) Advanced PCB CAM Scripting Services:

We offer comprehensive CAM scripting solutions for PCB fabrication teams looking to streamline manufacturing workflows, improve accuracy, and reduce turnaround times. Our custom-developed scripts enhance the capabilities of all major CAM platforms and are tailored to the specific needs of each client’s production environment.

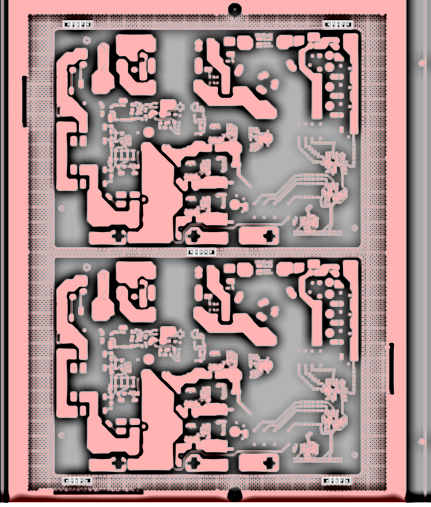

All Types of Custom Scripts From automation of repetitive tasks to intelligent design-for-manufacturing (DFM) checks, we build scripts that handle layer stack-up validation, drill map creation, gerber editing, netlist comparison, panelization logic, and more. These scripts help eliminate human error and maintain consistency across large production batches.

Software Agnostic Expertise Our scripting services are fully compatible with a wide range of industry-leading CAM software tools

Automation & Efficiency By automating time-consuming manual operations, our scripts free up engineering resources and significantly accelerate pre-production processes. The result? Faster deliveries, lower labor costs, and increased shop floor efficiency.

Custom-Tailored for Your Workflow We collaborate closely with your process engineers to develop and deploy scripting solutions that match your exact workflow requirements. Whether it’s for rigid PCBs, flex, HDI, or hybrid technologies, our approach ensures scripts that work with you, not around you.

3) Engineering Services

Our engineering suite is designed to support every stage of PCB production—ensuring precise execution, optimized efficiency, and exceptional end-product quality.

1. Quotation We provide quick and accurate quotation services tailored to the complexity and volume of your PCB project. Our evaluation includes material type, board structure, surface finish, and turnaround time to offer cost-effective pricing with full transparency.

2. CAM Editing Our skilled CAM engineers meticulously process and optimize your design data to align with fabrication standards and best practices. This includes layer alignment, drill and route adjustments, DFM (Design for Manufacturability) checks, and artwork editing—ensuring a smooth handoff to production.

3. Panelization Efficient panelization is crucial for yield optimization and production throughput. We create smart panel designs incorporating fiducials, tooling holes, break tabs, and V-cuts to reduce material wastage, streamline assembly, and maintain structural integrity during handling.

4. E-Test Output Generation To guarantee electrical reliability, we prepare comprehensive outputs for E-Test procedures. This includes netlist extraction, test point mapping, and open/short detection files—facilitating fast and accurate quality checks during mass production.

5. AOI Output We support your visual inspection process with high-precision AOI (Automated Optical Inspection) output files. These are designed to detect issues like misregistration, solder mask shifts, and etching defects, helping to identify problems early and maintain quality standards.

4)Reliable PCB Supply Services

We provide dependable and timely PCB supply solutions for diverse industries—offering everything from rapid prototyping to full-scale production. Our supply chain network is built for flexibility, speed, and quality assurance, ensuring boards are delivered exactly when and how you need them.

What We Offer:

- Prototype to Volume Production – Fast-turn single pieces to large-volume runs

- Rigid, Flex, Rigid-Flex, and HDI Boards

- Single-layer to Multi-layer PCBs

- Custom Materials & Stack-ups as per client specs

- Surface Finish Options – HAL,HASL, ENIG, OSP, Immersion Silver/Gold, and more

- Turnkey Support – End-to-end sourcing, quality checks, and logistics

Why Choose Us:

- Vendor Reliability – We partner with audited, industry-certified fabs

- Quality First – Every batch goes through strict inspection and testing

- On-Time Delivery – Globally optimized logistics to meet project timelines

- Technical Support – Our engineers are always available to resolve queries or review data

5)Professional PCB Assembly Services

We offer end-to-end PCB assembly solutions, delivering high-quality, fully assembled circuit boards ready for deployment. Our process is designed for flexibility, speed, and reliability—covering everything from prototyping to full-scale production.

Our Capabilities Include:

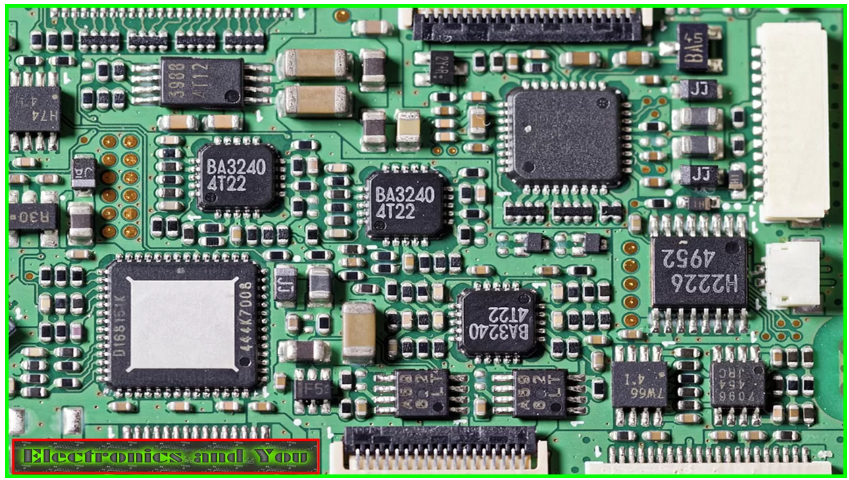

- SMT (Surface Mount Technology) Assembly – High-speed pick-and-place, fine-pitch components, and BGA/QFN packages

- THT (Through-Hole Technology) Assembly – Manual and automated soldering for durable, mechanically robust boards

- Mixed Technology Assembly – Seamless integration of SMT and THT components on complex assemblies

- Prototype & Low-Volume Assembly – Rapid turnarounds with minimal setup times

- High-Volume Production Runs – Scalable manufacturing with strict quality and traceability controls

- Component Sourcing – Full or partial BOM procurement with supply chain reliability

- Testing & Inspection – In-circuit testing (ICT), functional tests, AOI, and X-ray inspection to ensure zero-defect delivery

Why Work with Us:

- IPC-Class II & III Compliant Processes

- Flexible Turnaround Options

- Lead-Free/RoHS-Compliant Assembly Available

- Technical Support from DFM Review to Final Testing